Introduction

When it comes to diving, having a reliable and high-quality diving mask is essential for a safe and enjoyable underwater experience. But have you ever wondered how these diving masks are produced? What standards and processes are involved in their manufacturing? In this article, we will delve into the world of diving mask factory production, exploring the importance of quality standards, the materials used, and the steps taken to ensure the production of top-notch diving masks.

The Importance of Quality Standards

Diving masks are not just ordinary pieces of equipment; they are a lifeline for divers. Ensuring their quality is of utmost importance to guarantee the safety and comfort of divers underwater. Quality standards play a crucial role in achieving this goal. Let’s take a closer look at why quality standards are essential in diving mask factory production:

Safety

Diving masks must meet stringent safety standards to protect divers from potential hazards underwater. Quality standards ensure that the masks are durable, reliable, and capable of withstanding the pressures of deep-sea diving.

Comfort

A well-fitting and comfortable diving mask is essential for an enjoyable diving experience. Quality standards ensure that the masks are designed ergonomically, providing a snug fit without causing discomfort or pressure points.

Visibility

Clear vision is crucial for divers to explore the underwater world. Quality standards ensure that the masks are made with high-quality lenses that offer excellent visibility, minimal distortion, and anti-fog properties.

Durability

Diving masks are subjected to harsh underwater conditions, including saltwater, UV radiation, and physical impacts. Quality standards ensure that the masks are made from durable materials that can withstand these challenges without compromising their integrity.

Health and Hygiene

Diving masks come into direct contact with the diver’s face, making it essential to prioritize health and hygiene. Quality standards ensure that the masks are made from hypoallergenic materials, free from harmful chemicals or allergens that could cause skin irritations or allergic reactions.

Materials Used in Diving Mask Production

To understand the standards of diving mask factory production, it is crucial to examine the materials used in their manufacturing. Here are the primary materials involved:

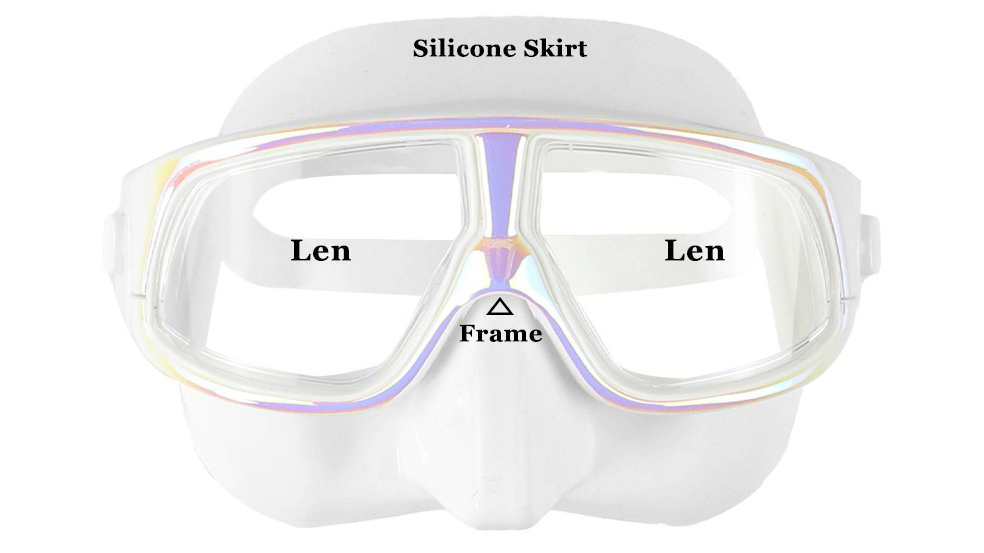

- Silicone: Silicone is a popular choice for the skirt, which is the part of the mask that creates a seal against the diver’s face. Silicone offers flexibility, durability, and hypoallergenic properties, making it an ideal material for ensuring a comfortable and secure fit.

- Tempered Glass: The lenses of diving masks are typically made from tempered glass. Tempered glass is stronger and more resistant to shattering than regular glass, ensuring the safety of divers in case of accidental impacts or pressure changes.

- Strap and Buckles: The strap that holds the diving mask in place and the buckles that allow for easy adjustment are usually made from high-quality, durable materials such as silicone or neoprene.

- Frame: The frame of the diving mask provides structural support and holds the lenses in place. It is commonly made from materials like plastic or lightweight metals such as aluminum.

Standards and Processes in Diving Mask Factory Production

Diving mask factory production involves several standards and processes to ensure the highest quality masks are produced. Let’s explore some of the key standards and steps involved:

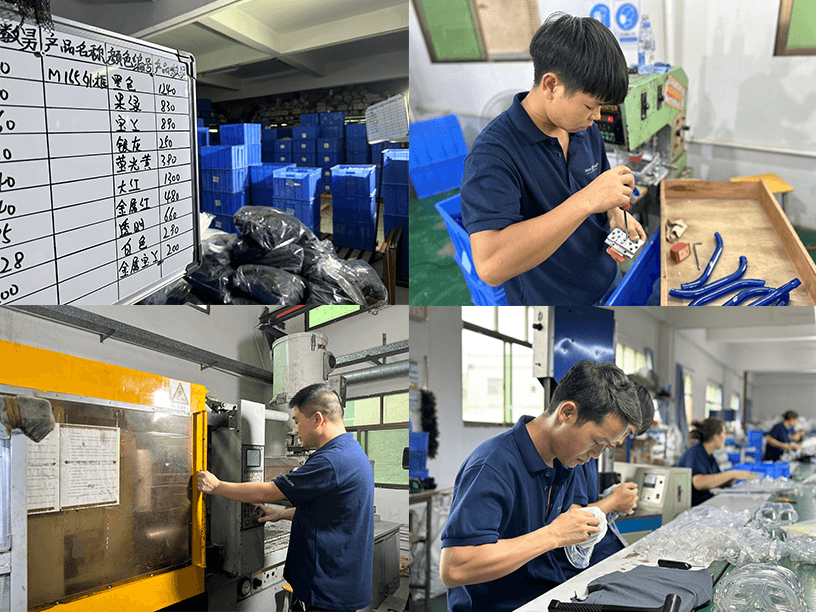

- Design and Prototyping: The diving mask production process begins with the design phase. Here, engineers and designers collaborate to develop innovative, ergonomic designs prioritizing comfort, visibility and safety. Prototypes are constructed and tested by the team to ensure standards are met.

- Material Selection: Material selection is crucial. Manufacturers carefully choose high-quality materials like silicone, tempered glass and others that meet industry standards—delivering durability, comfort and safety.

- Mold Creation: Once designs and materials finalize, molds are engineered for precise shaping. The team crafts molds that consistently form mask components. Then, injection molding transforms selected materials like silicone into parts through a controlled process.

- Injection Molding: Individual components emerge from molds as skirt, strap, frame and more. The team carefully assembles these into complete diving masks. Quality control actively ensures each mask satisfies specifications for safety, comfort and longevity.

- Assembly and Quality Control: Masks undergo rigorous testing by the team. Through evaluation, they confirm compliance with industry and regulatory standards—checking for water leaks, visibility and impact resistance. Certification allows distribution of masks that pass testing.

Frequently Asked Questions (FAQ)

Q: What material should a high-quality diving mask be made of?

A: Look for masks made of silicon or the Silicone. These materials are flexible, durable and resist cracking or fogging. Avoid inexpensive masks containing plasticizers that can leach chemicals.

Q: How can I tell if the lens is optically correct?

A: High quality lenses will be perfectly clear and distortion-free from edge to edge when viewed both in and out of water. You shouldn’t see any waviness or fish-eye effect.

Q: What lens treatments improve visibility underwater?

A: Top masks feature lenses with anti-fog coatings to prevent clouding as well as treatments like mirrored or tinted coatings. These reduce glare without sacrificing clarity.

Q: How thick should the skirt be?

A: Thicker, softer silicone skirts conform better to the face for a leak-proof seal. Avoid thin, hard plastic skirts that won’t compress easily.

Q: What signs indicate a flimsy frame?

A: Durable frames feel solid and don’t flex too much when squeezed. Low quality frames may creak under pressure or have connections that feel loose.

If frame doesn’t work for you, you can buy frameless scuba mask.

Conclusion

Diving masks are not just simple accessories; they are vital tools that ensure the safety, comfort, and enjoyment of divers underwater. Understanding the standards and processes involved in diving mask factory production is crucial to appreciate the level of care and precision that goes into creating these essential pieces of equipment. By adhering to strict quality standards, utilizing high-quality materials, and following meticulous production processes, diving mask manufacturers strive to provide divers with top-notch masks that meet their needs and exceed their expectations. So, the next time you embark on an underwater adventure, remember the importance of quality over everything when it comes to your diving mask.